Wake up, tidy processing area ready for the night

Help deploy gear for first shot.

Have dinner with crew and pull frozen product from snaps from previous night.

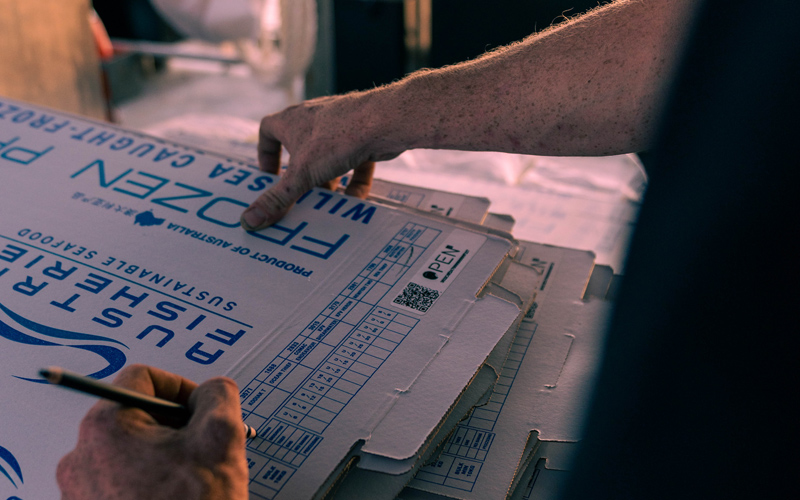

Fold and write on boxes ready for the night.

Chill out until hauling.

Assist with hauling and spilling out catch into the hopper.

Redeploy gear for 2nd shot.

Sort the catch, grade, weigh and box product.

Help the mate load the product into the snap freezers.

Clean up area ready for the next shot.

Chill out while helping skipper check try shots.

Assist with hauling and spilling out catch into the hopper.

Redeploy gear for 3rd shot.

Sort the catch, grade, weigh and box product.

Help the mate load the product into the snap freezers.

Clean up area ready for the next shot.

Chill out while helping skipper check try shots.

Assist with hauling and spilling out catch into the hopper.

Redeploy gear for 4th shot.

Sort the catch, grade, weigh and box product.

Help the mate load the product into the snap freezers.

Clean up area.

Haul last shot.

Sort the catch, grade, weigh and box product.

Help mate load the product into the snap freezers.

Help skipper drop the anchor.

Chill out.

Go to bed after a hot shower and breakfast.

Sleep

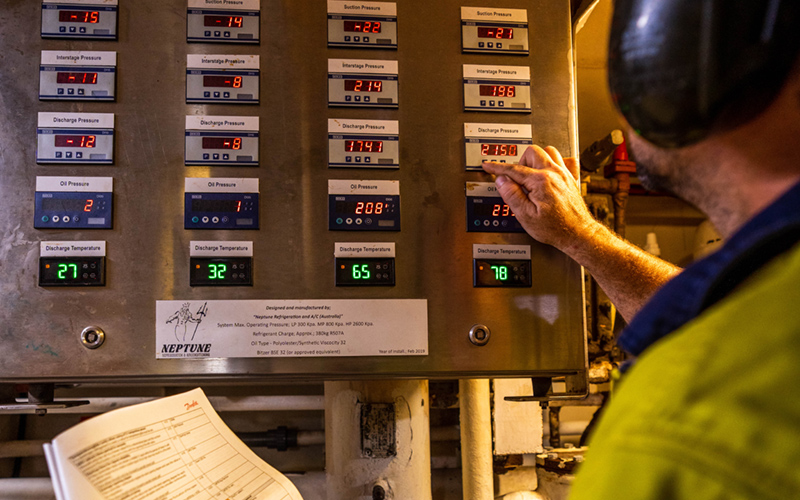

Wake up, start main engine and check and maintain fuel levels, water and other machinery in engine.

Help deploy gear for first shot net if required.

Have dinner with crew and attend to any maintenance needs of plant and equipment.

Chill out until hauling.

Assist with hauling and spilling out catch into the hopper.

Redeploy gear for 2nd shot net.

Sort the catch, grade, weigh and box product.

Help clean up area ready for the next shot.

Attend to any maintenance needs of plant and equipment.

Chill out.

Assist with hauling and spilling out catch into the hopper.

Redeploy gear for 3rd shot net.

Sort the catch, grade, weigh and box product.

Help clean up area ready for the next shot.

Attend to any maintenance needs of plant and equipment.

Sleep.

Assist with hauling and spilling out catch into the hopper.

Redeploy gear for 4th shot net.

Sort the catch, grade, weigh and box product.

Help clean up area ready for the next shot.

Attend to any maintenance needs of plant and equipment.

Haul last shot.

Sort the catch, grade, weigh and box product.

Shut off main engine after anchor is dropped.

Chill out.

Go to bed after a hot shower and breakfast.

Conduct vessel maintenance and upkeep.

Monitor engine and engineering systems.

Sleep.

Wake up, instruct first mate to get crew ready. Retrieve anchor.

Deploy 1st shot (lower trawl net gear).

Have dinner and drive vessel.

Haul 1st shot net.

Shoot away gear for 2nd shot.

Continue trawling and checking sounder, radar and operating radios to communicate with other skippers.

Haul 1st shot net.

Haul 2nd shot net.

Shoot 3rd shot net.

Continue trawling and checking sounder, radar and operating radios to communicate with other skippers.

Haul 3rd shot net.

Shoot 4th shot net

Have a sleep while the first mate takes over after processing.

Wake up to haul 4th shot net.

Report nights catch to fleet managers and Australian Fisheries Management Authority (AFMA).

Prepare to drop anchor.

Go to bed after a hot shower and breakfast.

Sleep

Austral Fisheries operates in “wild catch fisheries” where the product is caught & sourced with care. This means no two days may be the same. However, the days always start with fishing and end with the Skipper calling it a day, all the product is packed into the freezers and processing areas are clean.

Austral Fisheries are now hiring for a number of seagoing roles across their banana prawn operation season commencing March 2023.

Did you know there are over 50 careers in the seafood industry?

Let's deep dive into the seafood industry careers in the Northern Territory!

Teamwork takes wool from the sheep in the field to the next stage on its journey to become the natural fibres we wear and use. Shearing a mob of sheep requires a team of people to work together, all with specific roles and skills.

Bringing the sheep from the fields/paddocks is the responsibility of the farmer or the musterers. Depending on the topography of the farm they may use horses, bikes and specially trained sheep dogs to assist.

Once the sheep are yarded at the shed it is the responsibility of the shed hand to move them from the outside yards to the pens inside the shed.

Sheep are penned under or inside the shearing shed to keep dry the night before shearing commences.

When the shearers are ready to start work, the shed hand moves sheep from where they have been relaxing overnight into pens so the shearer can select one to begin shearing.

Each shearer has their own pen and the shed hand must ensure these are always full of sheep. Specially trained sheep dogs are often used in the shed to assist sheep movement.

The shearer is responsible for shearing the sheep by removing first the belly wool and then the remainder of the fleece as one piece. The shearer will treat any animal with cuts and alert the wool handler or farmer to any problems with the animal or its wool.

The wool handler works alongside the shearer and is responsible for gathering the belly wool and placing it in storage areas called ‘bins’, and then gathering the fleece and throwing it onto the wool table for inspection. The wool handler skirts the fleece and assists the wool classer as directed.

The wool handler is also responsible for sweeping the board between shorn sheep.

The wool classer is in charge of categorising the fleece according to various factors including fibre length and strength, colour and micron. The wool is split into different types as different lengths and types of wool are processed differently and best-suited to making different products.

The wool classer supervises the wool handlers and wool presser and records all wool processed and baled.

And sometimes the skills are passed from generation to generation. Mother and daughter wool classers

Under the direction of the wool classer, the wool presser fills, presses and closes bales in a wool press and records bale weight.

The presser is also responsible for stencilling each bale with the property name and key information about what type of wool is in the bale, based on how the wool classer has categorised it. This gives the wool buyers information about what the wool will be suitable to be used for so they know which wool to buy.

A dairy farming career can take you anywhere.

Whether it is growing your skills, travelling the world, owning your own business, or just doing something you love every day, dairy farming presents many work and life opportunities.

Bringing together people, animals, technology and the environment, dairy farming offers a meaningful role for everyone.

Explore a career in dairy, a job that matters.

Take a step through the farmgate and find out what it is like to work on-farm and be part of the dairy community.

This is a quick and practical way for preparing yourself to land a dairy farming job – simply click on the modules and follow the steps to explore each topic.

If you are new to dairy farming, start with Milk: the journey from farm to table and move through each module.